Compression Molding

Compression molding is a manufacturing method where material is placed into a mold cavity, compressed with heat and pressure, then cooled to form the desired shape.

Compression Molding Services

NICE Rapid offers custom compression molding services, tailored to meet diverse manufacturing needs. Our expertise lies in efficiently producing high-quality components by utilizing advanced techniques and precise mold design. Whether for automotive, aerospace, or consumer goods industries, we specialize in delivering cost-effective solutions with rapid turnaround times. With NICE Rapid, you can expect reliable custom compression molding services that ensure superior quality and consistency for your specific requirements.

Experience the Compression Molding Process with Us

At our facility, we boast a dedicated team of skilled professionals who work tirelessly to meet your deadlines. Our compression molding process begins with heating both the mold cavity and material to optimal temperatures. Once heated, the molten material is carefully inserted into the mold cavity, initiating expansion.

Central to this process is the application of pressure. Upon sealing the cavity, we apply high pressure to ensure thorough filling of all crevices and cracks. Our pressure ranges from 1,000 to 2,000 pounds per square inch (PSI), guaranteeing uniformity in the final product.

Through a combination of heat and pressure, the molten material is forced into the cavity. After allowing ample time for cooling, we extract the solidified product.

At Nice Rapid, we employ various techniques, but the fundamental principle remains constant: plastic or heated polymer is injected into the cavity and subjected to heat and pressure.

Ready to Start Your Next Project?

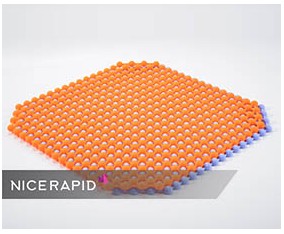

NICE Rapid Compression Molding Capabilities

We are completely carried out the whole production line from mold, refining, trimming, assembly with the most professional rubber vulcanizing equipment, the innovative R & D sprite, strong production capacity, strict quality control that makes us well to produce the material of NR, NBR, EPDM, SIR, CR, SBR, FKM, PU etc. All the raw materials can conform with ROSH, REACH and FDA, strictly enforce of ISO-9001 international quality system certification, we maintain good cooperation with domestic and foreign companies.

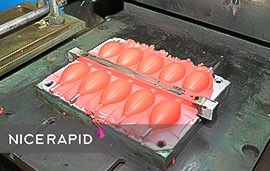

Strong Capability on Mold Making

Equipped with the world’s top mold manufacturing equipment, ensure that each link can get the most accurate and effective control.

Scientific Pre-forming Procedure

Introduced equipment such as pre-forming extrude, rubber & silicone strips cutting machines to ensure the accuracy or producing and the stability of products.

Precise Refining Operation

In order to effectively protect the excellent use of rubber, we formulated precise batching procedures. Continuously improve the banburying technology, as well as the high standard mixing practices, which enjoyed good reputation in the industry.

Professional Rubber Vulcanizing Machines

We have introduced the most professional rubber vulcanizing equipment, such as the tabulate vulcanizing machines, vacuum tabulate vulcanizing machines.