Revolutionizing Silicone Molding: The Power of 3D Printing Technology for Mold-Making

3D printing technology has already begun to change the face of manufacturing as we know it. And one of the most exciting applications of this technology is in the realm of silicone molding.

The ability to 3D print molds for silicone parts has several advantages over traditional mold-making methods. It is faster, more flexible, and less expensive. And as technology develops, these advantages will only become more pronounced.

If you are involved in silicone molding, you must know how this technology will change your industry’s landscape. In this blog post, we will explore the power of 3D printing technology for silicone mold-making and how it is revolutionizing the silicone molding industry.

This article will explore the traditional silicone molding process and its limitations and challenges. Silicone molding is a technique that uses silicone rubber as a material to create various shapes and products. Silicone rubber is a flexible, durable, and heat-resistant material that can be molded into complex forms and designs.

Traditional Silicone Molding Process

The traditional silicone molding process involves the following steps:

- First, a master model is created from the desired product or shape. The master model can be made from various materials such as wood, metal, plastic, or clay. The master model serves as a template for the mold.

- Next, a mold box is prepared to hold the master model and the silicone rubber. The mold box can be made from wood, metal, or plastic. The mold box should be slightly larger than the master model and have vents or holes for air to escape.

- Then, the silicone rubber is mixed with a curing agent and poured into the mold box over the master model. The silicone rubber should cover the entire master model and fill the mold box evenly. In addition, the curing agent helps the silicone rubber to harden and set.

- After that, the silicone rubber is left to cure for several hours or days, depending on the type and thickness of the silicone rubber. The curing time can vary depending on the temperature and humidity of the environment.

- Finally, the cured silicone rubber is removed from the mold box, and the master model is carefully separated from the silicone mold. The silicone mold is now ready to be used for casting various materials such as resin, wax, plaster, or metal.

The traditional silicone molding process has some limitations and challenges that can affect the quality and efficiency of the molding process. Some of these are:

- The master model can be damaged or distorted during molding due to pressure or heat. It can result in inaccurate or defective molds that do not match the original design or shape.

- Due to temperature or humidity changes, the silicone rubber can shrink or expand during curing. It can cause dimensional changes or warping of the molds that can affect the fit and alignment of the casted products.

- The silicone rubber can degrade over time due to exposure to sunlight, oxygen, moisture, or chemicals. As a result, it can reduce the durability and performance of the molds and cause them to crack or tear.

- Silicone rubber can be expensive and difficult to obtain in large quantities or custom colors. As a result, it can limit the molding process’s variety and creativity and increase production costs and time.

3D Printing Technology for Mold-Making

Mold-making creates a hollow shape that can be filled with a material to create a desired object. Mold-making is used for various applications, such as casting metal parts, making jewelry, creating sculptures, and more.

Traditionally, mold-making involves using materials like clay, wax, plaster, or silicone to create a mold by hand or using a CNC machine. However, in recent years, 3D printing has emerged as a new and innovative way of making molds.

3D printing creates objects by depositing layers of material on top of each other, following a digital model. As a result, it can create complex and intricate shapes that are difficult or impossible to achieve with conventional methods. Furthermore, 3D printing can create molds faster, cheaper, and more accurately than traditional methods.

One of the advantages of using 3D printing for mold-making is that it can reduce the number of steps and tools required to create a mold. For example, instead of using clay or wax to sculpt a mold by hand, 3D printing technology can directly print a mold from a digital model. As a result, it can save time, money, and materials.

Another advantage of 3D printing technology for mold-making is that it can create molds with high precision and detail. For example, 3D printing can print molds with fine features and textures that are difficult to replicate with conventional methods. As a result, it can improve the quality and appearance of the final product.

Depending on the material and application, different types of 3D printing technologies can be used for mold-making. Some of the most common types are:

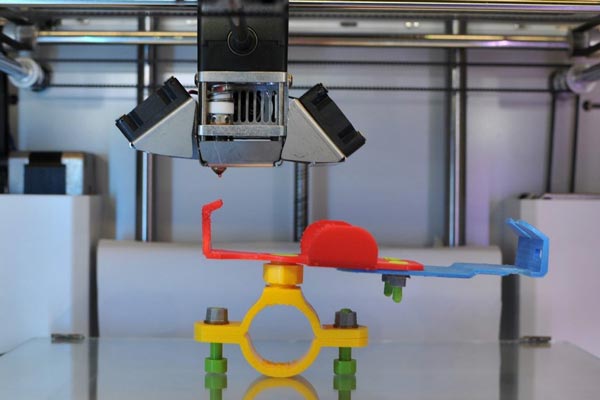

– Fused deposition modeling (FDM)

This type of 3D printing technology uses a heated nozzle to extrude a thermoplastic filament onto a build platform, layer by layer. FDM is suitable for making molds that can withstand high temperatures and pressures, such as metal casting molds.

– Stereolithography (SLA)

This 3D printing technology uses a laser to cure a liquid resin into a solid layer on a build platform. SLA is suitable for making molds that require high accuracy and smoothness, such as jewelry.

– PolyJet

This type of 3D printing technology uses a jetting head to deposit droplets of liquid photopolymer onto a build platform, which is then cured by UV light. PolyJet is suitable for making molds that require high flexibility and a variety of colors and materials, such as silicone molds.

The Future of Silicone Mold-Making

3D printing for silicone mold-making is still relatively new and evolving. However, it has the potential to revolutionize the industry and open up new opportunities and possibilities for both manufacturers and consumers.

One of the main advantages of 3D printing for silicone mold-making is that it can reduce the time and cost of producing custom parts. In addition, by eliminating the need for traditional tooling and machining, 3D printing can enable faster prototyping and testing and lower material waste and labor costs. It can also increase the accessibility and affordability of silicone mold-making for small businesses and hobbyists.

Another advantage of 3D printing for silicone mold-making is that it can enhance the design and functionality of parts. 3D printing can enable users to create impossible or unfeasible parts with conventional methods by allowing for more complex and intricate geometries. It can also improve the performance and aesthetics of parts and enable more customization and personalization.

A third advantage of 3D printing for silicone mold-making is that it can foster innovation and collaboration in the industry. By enabling users to experiment with different materials, shapes, colors, and textures, 3D printing can inspire new ideas and solutions for various problems and needs. It can also encourage more communication and cooperation among different stakeholders in the industry, such as designers, engineers, manufacturers, suppliers, and customers.

The future of silicone mold-making is bright and promising with the advent of 3D printing. However, some challenges and limitations need to be overcome, such as improving the quality and durability of parts, ensuring the safety and sustainability of materials and processes, and complying with the standards and regulations of different industries and markets.

Ultimately

3D printing technology is revolutionizing the silicone molding industry. With the ability to create highly detailed and customized molds quickly and easily, this technology is changing how businesses operate. If you want silicone molding services, get in touch with us to learn more about how we can help you.