by Nice Rapid | Mar 22, 2024 | Compression Molding

Compression molding uses a thermosetting process to shape materials such as rubber, composites, or resins. It’s a versatile manufacturing technique useful in rapid prototyping and low-volume manufacturing projects. This post examines the technology, its benefits, and...

by Nice Rapid | Feb 3, 2023 | Compression Molding

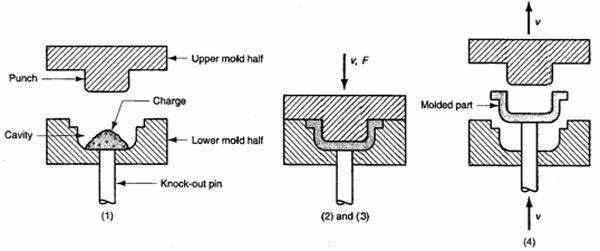

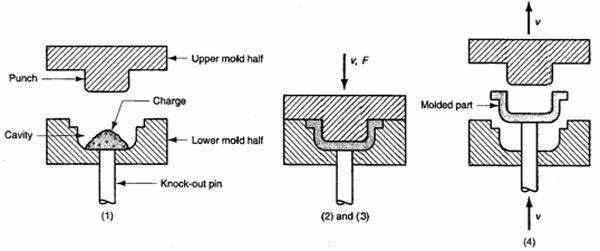

A common process used in the manufacturing of plastic products is compression molding. Like injection molding, it is a low-cost and tried-and-true method for making plastics. Warm plastic, often referred to as filler, is placed in a hot mold cavity and pressed under...

by Nice Rapid | Jan 9, 2023 | Compression Molding

Compression molding is a process that has been around for hundreds of years. It makes metal castings, plastic injection molded parts, and composite parts. This post will explore some surprising benefits of compression molding that you might need to learn about. High...

by Nice Rapid | Jan 6, 2021 | Compression Molding

If you are looking for one of the most versatile and flexible industrial procedures, then look no further; compression molding provides you with the perfect solution used by both large and small-scale manufacturers. The manufacturing technique is used to create a wide...

by Nice Rapid | Jun 23, 2020 | Compression Molding

The compression molding process is the simplest fabrication among the lot. The whole process is not complicated at all. As it involves inserting the material into the mold, closing it, applying pressure and heat, curing and finally opening the mold and removing the...

by Nice Rapid | May 6, 2020 | Compression Molding

Compression moulding is a process utilized to create stock shape materials that are both Thermoset and thermoplastic. It is done by placing a plastic material in the mold cavity that is produced by adding pressure and heat. The two factors combine to force the...