NICE Rapid Blog

Latest news and knowledge to share.

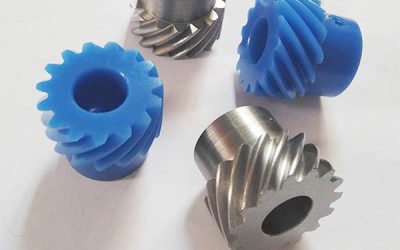

Advantages of Rapid Prototyping in 3D Printing and CNC Machining

The process of developing a product must include prototyping. Historically, this meant both producing working pieces on-site with poor accuracy and little resemblance to the final product. It also meant high prices and lengthy lead times. What does rapid prototyping...

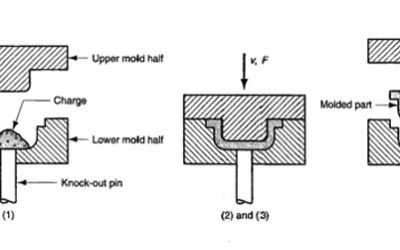

5 Surprising Benefits of Compression Molding That You Might Not Know About

Compression molding is a process that has been around for hundreds of years. It makes metal castings, plastic injection molded parts, and composite parts. This post will explore some surprising benefits of compression molding that you might need to learn about. High...

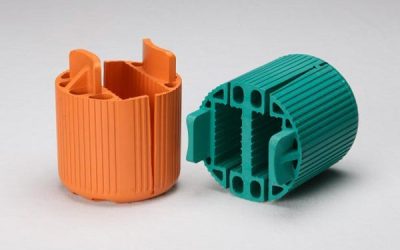

Using CNC Machining for Creating Plastic Designs

The plastic prototyping handle includes the utilize of plastics to create models. Sometimes recently mechanics begun utilizing CNC machining for model generation, metal was utilized to be the go-to fabric for forms. Typically since infusion molding utilized to be the...

Silicone Resin Molds vs. Plastic Molds: A Detailed Comparison

In the world of resin crafting, there are two main types of molds that people use: silicone molds and plastic molds. The two have pros and cons, and which one you use depends on personal preference. This article will look at both types of molds and compare them...

What is Vacuum Casting? Processes, Benefits and Uses

Vacuum-assisted pouring of liquid materials into silicone molds to create complicated shapes is known as vacuum casting. Latex and rubber elastomers are used in vacuum sealing of a fluid. Vacuum casting is also known aspolyurethanecasting due to the fact that...

The Complete Guide of Compression Molding: A Bridge from Prototyping to Full Production

If you are looking for one of the most versatile and flexible industrial procedures, then look no further; compression molding provides you with the perfect solution used by both large and small-scale manufacturers. The manufacturing technique is used to create a wide...

The Difference Between Rapid Tooling and Conventional Tooling

A critical step in manufacturing is tooling. This step involves producing the tools that will help create the product, and it includes cutting equipment, molds, jigs, dies, other custom parts. Manufacturers have lots of options in completing this process, and they...

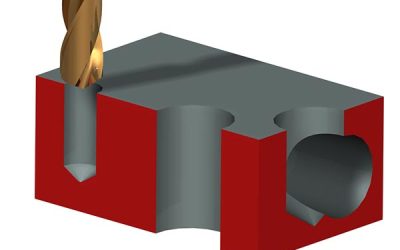

CNC Machining – Understanding the Secrets of Blind Hole

CNC machining has been growing in popularity in the manufacturing industry for several years. The shocking truth is that with this production technology, it has been easy to design and create several parts or products. Using the CNC machining process will help save...

Trends that Affect Plastic Injection Molding in 2020

Plastic injection molding is one of the popularly used plastic formation techniques with several industrial applications. The industry is evolving and expanding continuously. Customized plastic injection components are the best solution for different industries that...

The Difference Between Direct and Indirect Rapid Tooling

Tools or more commonly known as dies are needed in every manufacturing process. It has become significant that the annual turnout for the tooling industry is close to 60 billion dollars. In the past, the tool-making industry was dominated by Western economies like the...

The Role of 3D Printing in the Medical Field

3D printing is a process that has been helping one of the essential industries today – the medical field. Converts Computer-Generated Models to a Physical Model Surgeons, medical device developers, and researchers have discovered how to use 3D printing to treat and...

What Are the Indirect Methods of Rapid Tooling?

There are two broad, rapid tooling categories. One involves approaches indirectly making use of quick tooling master techniques for producing a mold. The other uses an approach directly where the machine of rapid tooling creates the real core and cavity mold insert. ...

Prototype and Manufacturing Services Near By

Rapid Prototyping Services

Turn your ideas into reality fast with our rapid prototyping services. From concept to 3D printing, we bring your vision to life quickly and accurately. Stay ahead of the curve and accelerate your product development process with us.

Silicone Molding

Experience seamless production with our silicone molding expertise. Our precise techniques ensure high-quality, custom molds that bring your designs to life with exceptional detail and durability. Whether you’re crafting prototypes or mass-producing products, our silicone molding services offer efficiency and reliability, empowering you to achieve your goals with confidence.