You don’t have to be an experienced molding operator to understand the level of complexity of these devices. The technology might be user-friendly, but maintenance is necessary to keep these devices running correctly. Getting the proper schedule to plan tune-up will keep molding machines up and running for a very long time.

Your hardware is the one determining how many rounds of maintenance you should plan in the year. If you’re running an integrated workshop, you have more than one piece of equipment to handle all manufacturing procedures. Scheduling maintenance for all of them can be a logistical nightmare. We offer some advice here to manage this process more efficiently.

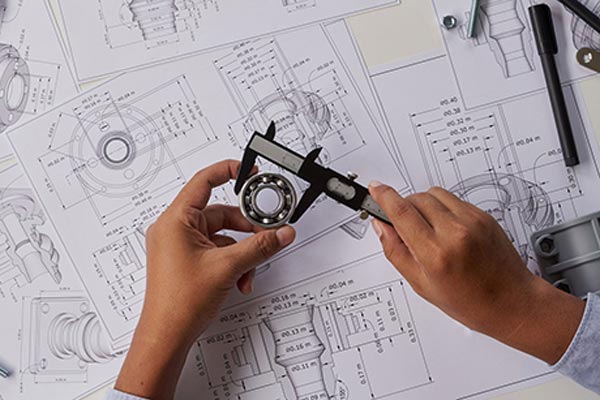

CNC machine parts

Daily Revisions

You should supervise plastic molding devices, CNC machining tools, and everything requiring an operator’s hand before starting a shift. This also makes the technician more acquainted with the machine he’s operating while learning more about it. Daily morning checkouts on all devices are essential to keep your workshop up and running.

What poses a problem for one employee should be something easy to fix by the equipment’s primary operator. The operator can handle small steps such as lubrication and replacement of worn-off parts with time. These team members can pick up more experience until they can assist external technicians by letting them know the quirks of their equipment.

General Checks

Workshops can conduct more in-depth revisions made in accordance to press cycle countdowns. You must check medium-sized molding machines with basic open-shut delivery systems every 200 million cycles. Big-sized devices with the same features can take press cycles of 500 million units before requiring revisions.

All revisions are done the same way: a technician takes apart the equipment, looks for defects, and gets plates, and other parts cleaned up. This also includes a close inspection for any deficiencies and signs of wear. Whatever is damaged gets replaced. Mold machines handling multiple moving parts require maintenance after 100 million reproduction cycles.

Deep Maintenance Procedures

These revisions are destined for all molding devices reaching the milestone of a million press cycles. The most crucial ones are mold alignments, plates, and other uninstalled parts to be compared with baseline new models. This routine requires a full stop on all machinery operations to make thorough inspections on every level. If the mold withstands a few more cycles, it will be put in place again. Otherwise, it’s replaced.

Most components are also inspected, looking at performance issues, and measured to their original dimensions. If any of them shows wear or underperformance, it’s replaced. If the machine uses water cooling systems such as plugs and water fittings, these get replaced with new ones. This is one of the most expensive maintenance procedures, but it’s also the one keeping these machines turning a profit.